Festive season plant closures

The festive season is fast approaching, which means our sites will soon be closing for the holidays and our teams will enjoy a well deserved break.

To help you prepare your projects, we’ve listed below the dates and times that our sites will be shutting, as well as the dates and times that our sites will be reopening in the new year. Get your work booked in early if you need it before the holidays!

Premier Galvanizing Corby

Close: Thursday 21 December 2023, 4.30pm.

Open: Tuesday 2 January 2024, 7.00am.

Premier Galvanizing Hull

Close: Friday 22 December 2023, 1.00pm.

Open: Tuesday 2 January 2024.

To see the open/close dates of the other plants in the Joseph Ash Group, click here.

Next page

The Joseph Ash Group takes immense pride in its expansive network of nine plants spanning the United Kingdom, from the northern Yorkshire region to southern county of Kent. This month, we turn our attention to our facility in Yorkshire, Premier Galvanizing Hull, to showcase its exceptional capabilities and modern amenities.

Historical background

The galvanizing industry in Yorkshire flourished during the 19th century, driven by the region’s industrialisation. Hull experienced significant growth in the galvanizing sector thanks to its thriving maritime trade. Situated on the River Humber with a bustling port, Hull became a central hub for importing and exporting goods. Galvanizing was pivotal in safeguarding metal components used in ships, including anchor chains, fittings, and various marine equipment.

Throughout the late 19th and early 20th centuries, the galvanizing industry in Hull continued to thrive. Several galvanizing companies emerged to meet the growing construction, engineering, and agriculture demand. Technological advancements and modernisation in the latter half of the 20th century transformed the galvanizing process, propelling the industry forward.

In 2000, Premier Galvanizing opened its first plant in Yorkshire. Today, the galvanizing industry in Hull remains a vital sector, serving diverse industries both locally and globally.

Location

Premier Galvanizing Hull is located within the Stoneferry Business Park in the East Ridings of Yorkshire. With an extensive fleet of vehicles, we cater to galvanizing needs in Yorkshire, Nottinghamshire, Teeside, and the Northeast, ensuring timely service for our valued customers.

Galvanizing services at Premier Galvanizing Hull

Whether fabricators require a small amount of steel galvanized for a sculpture or 100 tonnes for a new bridge, Premier Galvanizing Hull is here to assist.

Bath size

Premier Galvanizing Hull’s bath dipping size measures 7.0m x 1.2m x 3.2m, with a maximum dip weight capacity of 4 tonnes.

Additional services

In addition to our core services, Premier Galvanizing Hull offers the following amenities to our customers:

Collection and delivery service: Regardless of your location or the destination for your fabrications, we provide efficient steel transportation. Our fleet includes xx articulated vehicles capable of carrying 22 tonnes each and rigid vehicles that can accommodate up to 10 tonnes.

Full technical support: Our comprehensive technical support ensures customers receive guidance and assistance at every stage, guaranteeing a smooth galvanizing process.

Packing and bundling: We can bundle, pack, and label your steel per your requirements. We can accommodate your needs if you need items delivered to the end user or prepared for export or containerisation. Upon request, we can issue certificates of conformity, and all work is conducted following BS EN ISO 1461 standards.

On-site storage: With ample on-site storage capacity, Premier Galvanizing Hull allows customers to conveniently store materials before and after the galvanizing process.

Shot blasting and powder coating: These services are available through our trusted external subcontractors.

Flexibility

At Premier Galvanizing Hull, we fully understand the value of meeting time-sensitive demands and adhering to strict deadlines. We have extended opening hours for drop-offs and collections to ensure optimal customer assistance. Additionally, we provide expedited turnaround times, such as overnight or within 24 hours (by prior arrangements). We aim to deliver prompt and efficient service, catering to your specific requirements.

Committed to excellence and compliance

At Premier Galvanizing Hull, we prioritise excellence in all aspects of our operations. This includes maintaining the highest occupational health and safety standards, quality management, and environmental management. Our certifications include BS EN ISO 1461, ISO 45001, NQA ISO 9001, ISO 14001, and OHSAS 18001.

Dedicated team

The Hull team comprises dedicated individuals with extensive knowledge and experience in their roles. We strive to provide our customers with the highest level of service. We also consider ourselves an integral part of your team, ensuring your needs are met with utmost care and professionalism.

Key personnel at Hull

Andrew Tweddle serves as the Divisional Manager at Hull, while Chris Young oversees the Transport and Production Manager role.

Contact us

To book your projects with us or for any enquiries, please don’t hesitate to contact the Premier Galvanizing Hull team today!

Next pageThe Joseph Ash Group takes pride in its extensive network of nine plants across the UK, from Medway in the South to Hull in the North. This month’s newsletter highlights our Northamptonshire facility, Premier Galvanizing Corby. We’re putting a spotlight on Corby to showcase its remarkable capabilities and state-of-the-art amenities.

As we celebrate Premier Galvanizing Corby’s achievements, we are delighted to announce that next month marks a special occasion for the plant. Read on to find out more!

History

Premier Galvanizing Corby is in a region of England historically tied to the growth and development of steel and ironworks during the Industrial Revolution. And where there’s steel, there’s galvanizing.

Galvanizing became essential as the steel industry grew in Corby. It was particularly crucial for the construction sector, where steel structures and components were exposed to the elements. Galvanized steel offers superior durability and resistance to rust. This makes it ideal for a wide range of applications, including bridges, buildings, and infrastructure.

In recent years, Corby has experienced a resurgence in its steel industry. This has been driven by investments and the growth of new businesses. Galvanizing remains vital in the town’s steel sector, ensuring the longevity and corrosion resistance of steel products manufactured there.

Today, galvanizing companies in Corby continue to employ advanced techniques and technologies to provide high-quality galvanized steel coatings. Premier Galvanizing caters to various industries: construction, automotive, agriculture, and infrastructure.

Location

Premier Galvanizing Corby is located on the Willowbrook Industrial Estate. With its extensive fleet of vehicles, it covers customers’ galvanizing needs from London, Berkshire, Buckinghamshire, Hertfordshire, Cambridgeshire, Bedfordshire, Leicestershire, Lincolnshire, Nottinghamshire and Derbyshire, as well as the Midlands.

What is galvanized at Premier Galvanizing Corby?

Whether a fabricator needs a small amount of steel galvanized for a gate or railings or 100 tonnes of steel for a new building development, Premier Galvanizing Corby can help. We pride ourselves on getting it right the first time, on time, and every time to meet the varied needs of our customers.

Bath size

The bath dipping size at Premier Galvanizing Corby is 7.5m x 1.3m x 3.0m, and the team can dip 4.8 tonnes.

Additional services

As well as core services, Premier Galvanizing Corby offers the following customer amenities:

Collection and delivery service: Wherever you are or wherever the end destination for your fabrications is, Premier Galvanizing can transport your steel. We operate a fleet of four articulated vehicles capable of carrying 22 tonnes each. Plus eight rigids which can also carry up to 10 tonnes.

Full technical support: Providing customers with comprehensive technical support, offering guidance and assistance at every stage.

Packing and bundling: We can bundle, pack, and label your steel at your request. Let us know your requirements. Especially if you want us to deliver your items to the end user or prepare them for export or containerisation. Certificates of conformity can be issued upon request, and all work is conducted following BS EN ISO 1461.

On-site storage: Premier Galvanizing Corby offers ample on-site storage capacity, allowing customers to store materials conveniently before and after galvanizing.

Shot blasting and powder coating: Through an external subcontractor.

Flexibility

Recognising the importance of meeting customers’ time-sensitive demands, the team at Corby fully understands the significance of strict deadlines. We have extended opening hours for drop-offs and collections to provide the best assistance. Moreover, Corby offers expedited turnaround times, including overnight and within 24 hours, through prior arrangements, ensuring prompt and efficient service.

Committed to excellence and compliance

Premier Galvanizing Corby prioritises excellence in everything it does, including maintaining the highest occupational health and safety standards, quality management, and environmental management. Certifications include BS EN ISO 1461, ISO 45001, NQA ISO 9001, ISO 14001, and OHSAS 18001.

People

At Corby, we have a dedicated team of individuals with a wealth of knowledge and a sincere passion for their roles. From skilled shop floor operatives to transport and truck drivers, meticulous health and safety experts to the efficient administrative team, we work collaboratively to ensure that our valued customers receive the utmost service and see us as part of their team.

The Divisional Manager at Corby is David Prattis, and the Commercial Manager is Paul Martin. Contact Paul today to book your projects.

Finally, Corby comes of age!

As we celebrate the achievements of Premier Galvanizing Corby, we are delighted to announce an upcoming special occasion. The plant opened its doors in Corby in July 2002, so next month, it turns 21!

When the plant first opened, it had 13 team members. Now it has 44.

Happy 21st birthday to the team at Corby!

Next page

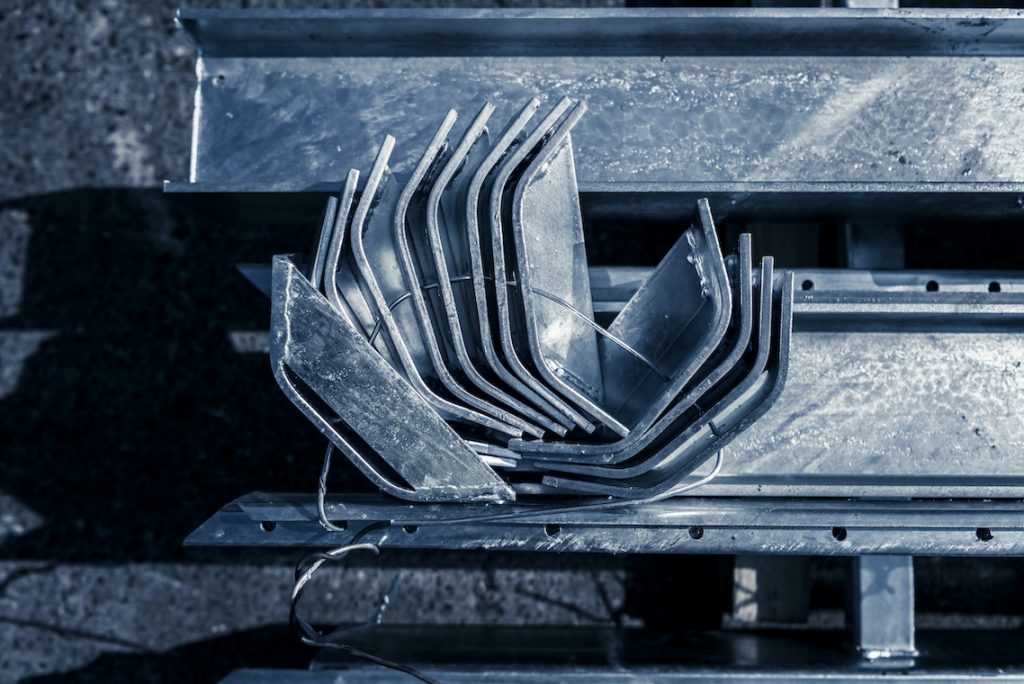

We’re pleased to announce the recent installation of a new galvanizing kettle at our Hull plant.

It’s quite a logistical exercise to remove an existing kettle and replace it with a new one. Commissioning and planning the changeover takes months. And the installation – including removing/recycling existing zinc, dismantling the bath, fitting a new bath, and adding new zinc ingots – takes a whole week. The bath also had to be transported from Germany first!

The bath dimensions are the same as before: 7m length x 1.2m wide x 3.2m deep. However, it has a thicker wall than previously (now 60mm instead of 50mm).

For health and safety reasons, it’s typical to change galvanizing baths every 7-10 years as the wall thickness degrades over time, specifically in areas with a temperature difference, such as the ‘wash line’ and above the Dross protection. Structural integrity is crucial for health and safety, so even though we still had a few years left in our previous bath, we always opt for the cautionary approach.

Thanks to W. Pilling in Germany who provide all our kettles, and the following companies who helped with the installation: Projector Lifting Service, Zinco, Westech and Thermetal Metallurgical Furnace Engineers.

Next page

To help you plan ahead for December and January, please find below the festive period opening hours for our plants:

Premier Galvanizing Corby

Will be closed from 23 December 2022. (Last day for deliveries is 22 December 2022.)

Will re-open on Tuesday 3 January 2023.

Premier Galvanizing Hull

Will be closed from 22 December 2022. (Last day for deliveries is 21 December 2022.)

Will re-open on Tuesday 3 January 2023.

On Monday 19 September 2022, all Premier Galvanizing plants will be closed as a mark of respect for Her Majesty Queen Elizabeth II and the National Day of Mourning.

The team at Premier Galvanizing extend our heartfelt sympathy to the Royal Family at this sad time.

Next pageSave the date for Thursday 20 October 2022

In conjunction with the Galvanizers Association, we will host an Open Day at our Premier Galvanizing Hull plant.

Would you like to attend to see how we operate? If so, book a tour today.

- Watch how steel is dipped into zinc in the galvanizing baths to protect it from rust and corrosion

- Find out about the sustainability of galvanized steel and how it fits into the circular economy

- Meet our team members and ask any questions you have about hot dip galvanizing, shot blasting, powder coating and steel protection.

- Talk to our technical teams for advice on designing steel for galvanizing.

If you’re unable to attend the Open Day at Hull, our sister Joseph Ash plants (at Chesterfield and Telford) will also be taking part.

Please get in touch if you’d like more information.

Next page

The Jubilee Bank Holidays will soon be upon us, which means our plants will be closed.

If you have projects that need completing around this time, book the work in early so that we can complete it for you.

All Premier Galvanizing and Joseph Ash Galvanizing plants will be closed on Thursday 2 June and Friday 3 June 2022.

Enjoy your Bank Holidays too!

Next page

The Easter bank holidays will soon be upon us, which means our plants will be closed for the long weekend, giving our team members a well-deserved break.

If you have projects that need completing around this time, book the work in early so that we can complete it for you.

All Premier Galvanizing and Joseph Ash Galvanizing plants will be closed from Friday 15 April to Monday 18 April 2022.

We hope you have a great bank holiday weekend too!

Next page

As the steel construction industry moves to net-zero carbon by 2050, embracing the ideals expressed at COP26, Premier Galvanizing is playing its part.

Some of our decarbonisation initiatives include minimising energy usage, reusing waste heat to warm pre-treatment tanks, and improving burner efficiency. Plant emissions are also carefully controlled to ensure neighbouring communities are not adversely affected.

Our latest carbon reduction project has changed the lighting at all plants and our Head Office to be more energy efficient.

In late 2021 we engaged MODO to replace all the high-powered traditional lighting at three sites (Hull, Chesterfield and Head office) with LED fittings and motion sensors.

For example, at our sister plant in Chesterfield, MODO replaced over 300 light fittings. The company also installed motion sensors in low traffic areas, which power the lights on immediately when motion is detected, dimming down when the site is inactive and then powering off.

The switch to Modo LED also reduced the CO2 emissions by a massive 117 metric tonnes, equivalent to the average car driving 286,867 miles!

Please get in touch to find out more about carbon efficiency projects at Premier Galvanizing.

You can also see how we are committed to preventing pollution and minimising environmental impacts by viewing our Green Plan interactive infographic, newly published on our website.

Next page