The environmental impact of hot dip galvanizing

Is the hot dip galvanizing process sustainable?

If you are looking for an environmentally-friendly finishing process to prevent corrosion, then hot dip galvanizing is the answer. Hot dip galvanizing is the best economical and beneficial corrosive protection for your steel fabrications.

A typical hot dip galvanized coating would be 85 microns thick. With Zinc corrosion rates in most European countries often less than 1 micron a year, a hot dip galvanized coating may provide decades of maintenance free life. Beneficial for the pocket as well as the environment.

Perhaps the most striking combination of steel structures and galvanized coatings is the Eden Project. As the largest plant enclosure in the world, this is a showcase for global bio-diversity, built with a hot dip galvanized steel frame for the lightest and most ecological solution.

How we make the process sustainable

Galvanizing steelwork is highly sustainable and produces minimal waste product; any waste products produced such as ash and dross are recycled back into this and many other industries.

When steelwork is withdrawn from the galvanizing bath any zinc which does not form a coating on the metal remains in the galvanizing bath. This is due to the metal’s non-ferrous properties, which makes it indefinitely recyclable without loss of physical or chemical properties.

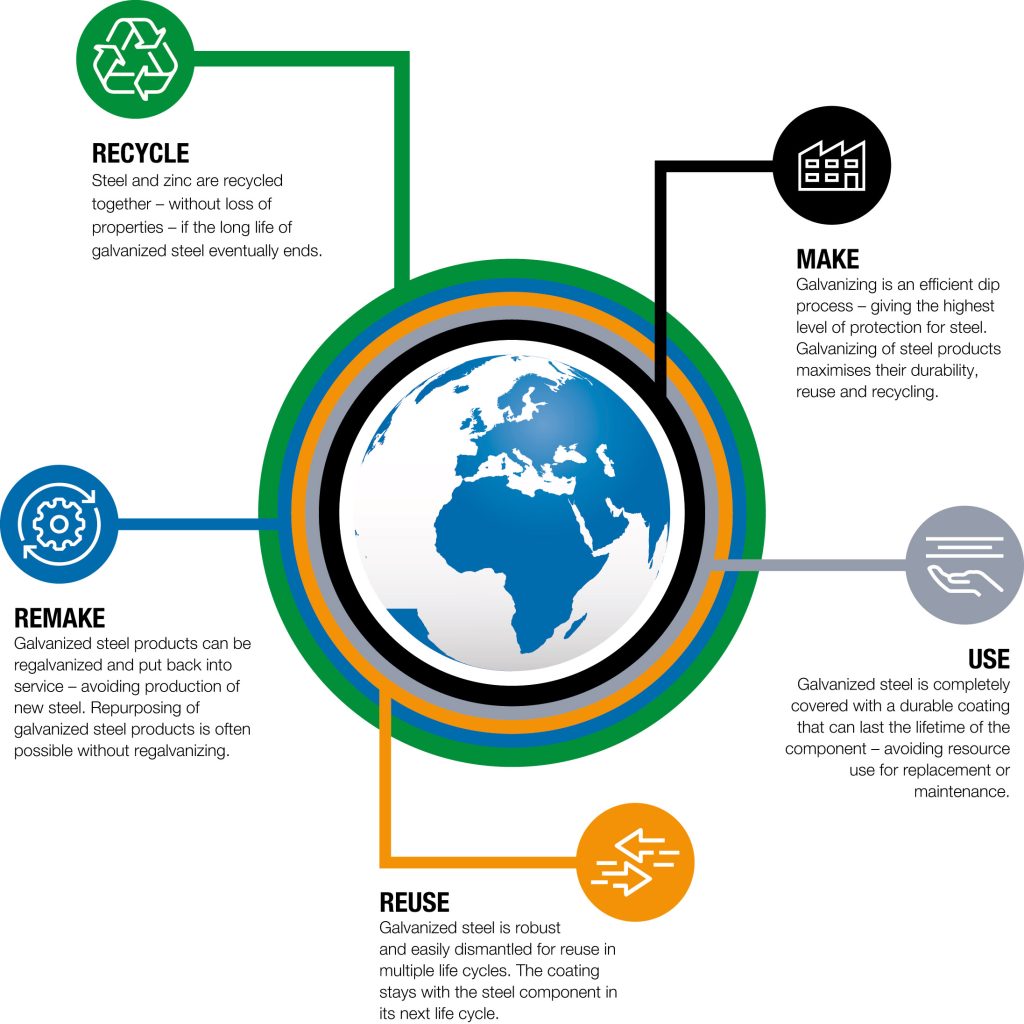

On the Joseph Ash Galvanizing website we have an interactive animation which shows how the process remains sustainable at every stage.

At Premier Galvanizing we care about the planet

When processing steel for we work hard to protect the environment, through an ever-growing list of recycling activities with processes supported by an Environmental and Sustainability Policy. We also follow the principles of a circular economy (‘The sustainability of galvanized steel‘) and operate within a framework of a self-imposed Environmental Management System based on internationally recognised standards.