A double dip for a Kent based swimming pool

The galvanizing project

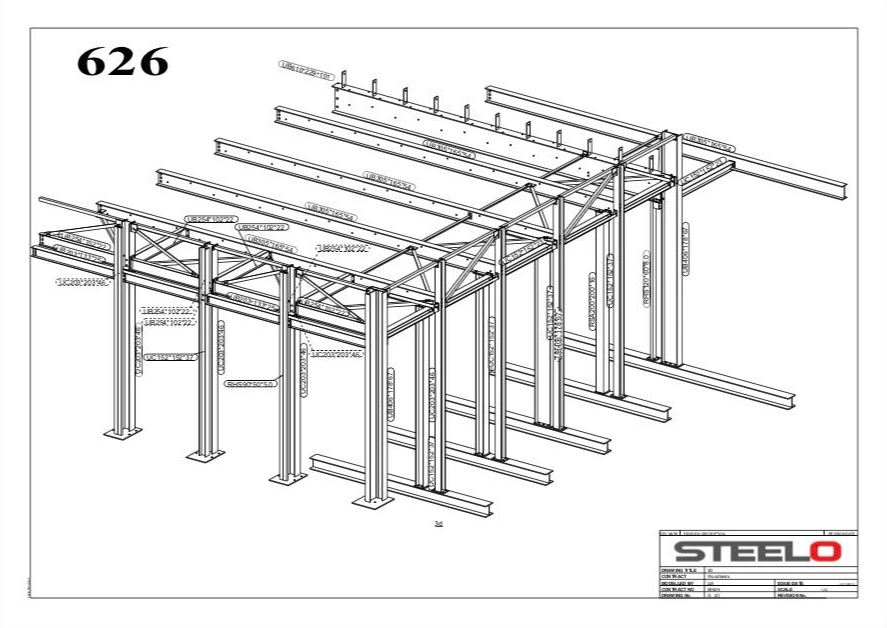

Galvanizing 68 steel beams for a Kent-based residential swimming pool.

The challenge

Steelo is a structural steel fabrication company based in Hounslow. Originally set up as a one-man venture in Isleworth by founder Michael Krajewski, the company has grown in size to over 20 people with a 12,000 square foot plant near Heathrow.

The company fabricates everything from beams to frames to posts and regularly uses Premier Galvanizing to protect the steel with a hot dip galvanized finish.

Steelo was recently involved in a project to provide steel beams for a swimming pool, as part of a residential property in Bromley. The property – called Woodlands – is a mansion being built in the Neo-Palladian style, with stunning landscaped gardens. With three floors, plus a basement, the impressive property includes seven bedrooms, a cinema, a grand staircase, a bar, a gym, family rooms, underground car parking with a car lift, and a library.

The builders for the project are the Mormac Group, and the architects are AV Architects.

Steelo was commissioned by the Mormac Group to fabricate 68 steel beams, with a tonnage of 5295kg. To protect the steel from erosion and rust, the beams had to be hot-dip galvanised and Steelo called in Premier Galvanizing to manage this part of the project.

As a keen supplier to Steelo, Premier Galvanizing was only too happy to take on the role. Team members from the Corby plant managed the galvanizing, as well collecting the steel from Steelo and delivering it back once it had been processed.

The end result

Magdalena Rajkowska, General Manager, from Steelo said: “It was a challenging project due to the number of beams involved in the pool build. We chose Premier Galvanizing as they always provide a quality galvanizing job for us and can manage the collection and delivery too – taking the admin out of some of the logistics.”

Rajkowska added: “Once the beams arrived back from Premier Galvanizing’s Corby plant, our design engineers marked the beams in order to help team members from the Mormac Group to identify them on site.”

Next page