Hot dip galvanizing

The process and benefits

Hot dip galvanizing is a long lasting, low maintenance method of protecting steel against corrosion. It has zero drying time, is environmentally friendly, and has good impact and abrasion resistance.

Prior to galvanizing, steel fabrications are submerged in hydrochloric acid to remove all rust and mill scale to provide a chemically clean surface.

Only when the surface of the material has been cleaned can hot dip galvanizing take place. If there are any contaminants left on the steel, the steel will not galvanize fully. The steel fabrications are then ‘dipped’ in a molten bath of zinc that is heated to approximately 450°c.

Once hot dip galvanizing has taken place, the zinc is metallurgically bonded to the steel substrate producing a protective coating. At this point the steel has been protected from corrosion and it is ready for the end user.

Hot dip galvanizing at Premier Galvanizing

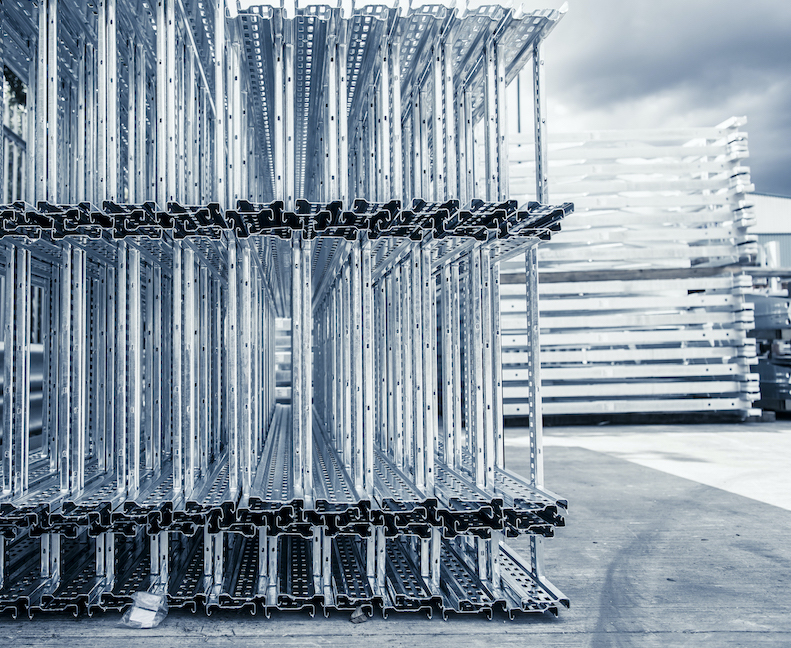

With different bath sizes at our Premier Galvanizing (and Joseph Ash Galvanizing) plants, we can hot dip galvanize everything you fabricate, from lighting columns to bridges, fencing products to industrial flooring, structural sections to access support steelwork, and motorway guardrails to bracketry and fixings.

When it comes to corrosion protection, our dedicated and expert workforce and large and modern HGV fleet provide you with the highest standards of hot dip galvanizing quality and service available.

Additionally, our dedication to adding value at every step ensures we deliver the optimal possible results and service. For example, we never forget that hot dip galvanizing is a hands-on process, the final quality of which rests on the skill of our galvanizing operatives.

All hot dip galvanizing at Premier Galvanizing plants adheres to the BS EN ISO 1461 and BS EN ISO 9000 quality assurance specifications.

To protect any parts of the steel that perhaps need to be drilled or cut after galvanization, spray them with Galvsafe – a unique galvanizing zinc repair spray developed by Joseph Ash at the request of our customers.

To protect any parts of the steel that perhaps need to be drilled or cut after galvanization, spray them with Galvsafe – a unique galvanizing zinc repair spray developed by Joseph Ash at the request of our customers.